If you ever heard about the welding table, then you definitely how important it is and you might have a question “how does a welding table work?” In this post, we will let you know about all the aspects of this table.

What is a Welding Table?

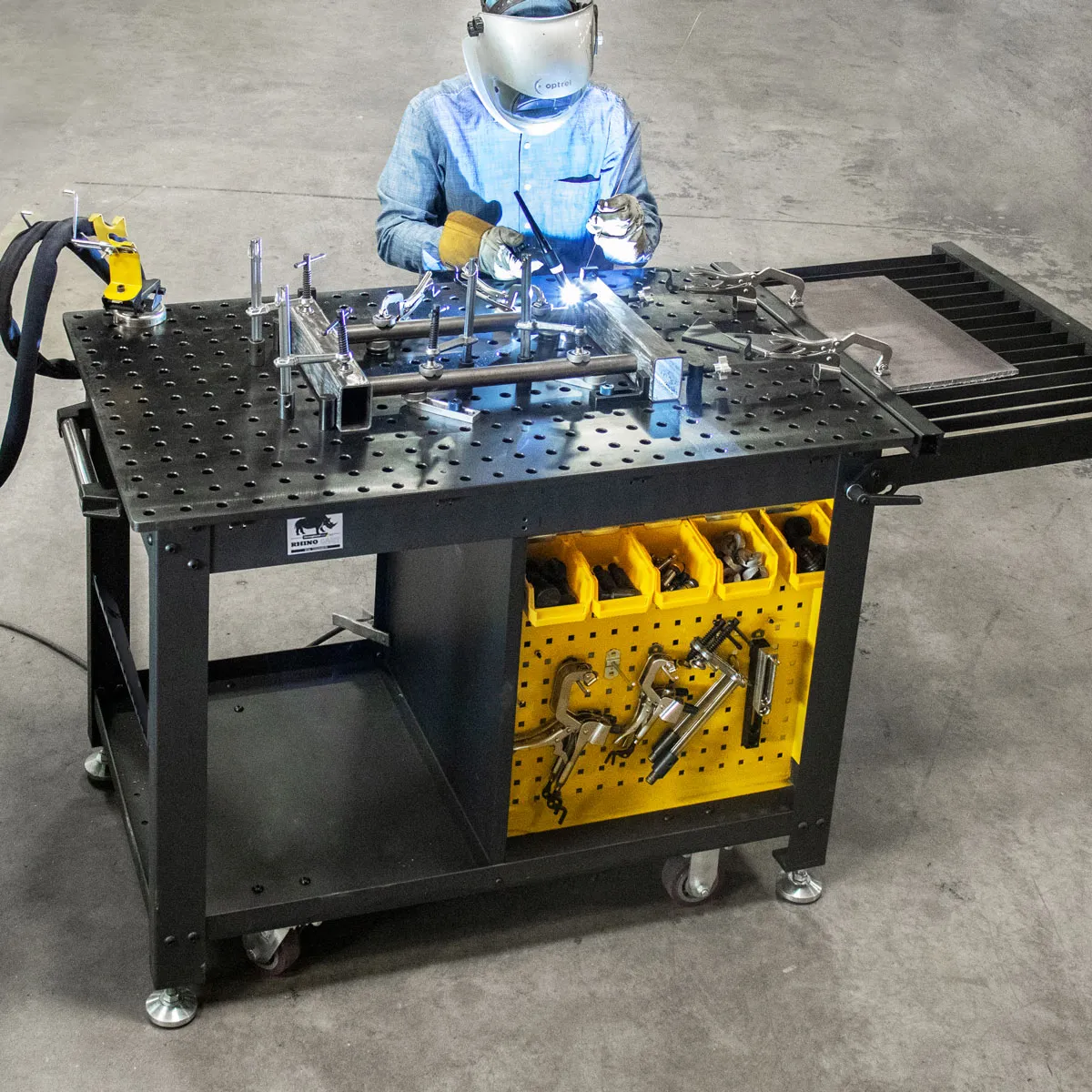

A Welding table is a flat metal work waist-level platform that works like a workbench. It is specifically designed for withstanding the rigors and high temperatures, regular impact, and plenty of friction that comes with welding. It prevents fire hazards and electric shocks.

People use it while they are working in metal fabrication with welding. Moreover, it will provide you not only a stable area for work but also assistance with squaring and measuring. As these tables are made of steel, they can withstand rigors and intense heat. Generally, the size of the welding tables ranges from 20” x 40” to 6.5” x 13”.

How does a welding table work?

There are several jobs where the welding table is versatilely used as a flat platform for measuring, gauging, and squaring corners. This kind of table is also used for bending brakes and jigs. Without any extra effort or difficulties, a welding table can be the perfect platform for doing all of that. It is specially designed to keep all the things on it keep in place so it isn’t sliding around on the table.

Having a clamp on this table is the most useful thing. Because while welders are working with it, this clamp will help to hold cables out of the way. There are some other accessories that will help you to work such as hot-rolled steel grill tops, drawer-like trays, and so on.

What is a Welding Table used for?

A Welding Table is an essential thing for welders. It makes welders’ work easy, safe, and comfortable. When someone is going to buy this table, their first thought is “Is a Welding Table really worthy to buy?” Actually, if you are someone who is thinking about it, then we will tell you details about it.

A Welding Table is used for the following purpose –

- To get a stable flat platform to work on.

- It withstands the rigors and high temperatures while welding.

- For squaring and measuring the corner of any metal.

- For bending brakes and jigs.

- Keep in place all the cables.

- Ensure safety during work.

- To ensure consistent quality results.

- To get a manageable platform for Heavy and large equipment.

- Help to get assembled while welding.

- For Electrical grounding

Why does the Welding Table have holes?

If you have ever seen Welding Table, you definitely saw many holes in it and wonder why the Welding Table has holes. Actually, the welding Table has holes for holding accessories kept in place with clamps, jigs, vices, and stops. These holes basically hold everything so tightly on it that can move easily while welding and assembling.

What to consider when choosing a welding table?

When you will go to buy a welding table, you will have to keep in mind these few following things –

Quality: The quality of a Welding Table has to be good. Otherwise, while you are working on it, you won’t get the best user experience.

Table size: The size of the table is actually one of the most important things that you have to understand. Because it needs to buy according to the size of your working metals and accessories.

The ability to withstand heat: As you are going to buy this table for working in high heat. So the table must have the ability to withstand high heat.

Load Capacity: Welding Table carries so much load during work. So please check its load capacity.

Safety: The most important thing is safety when you are working with heavy materials, high, and electricity. So you should have a Welding Table that provides you full safety.

There are so trustworthy websites and e-commerce sites from where you can also order a good quality ready-made welding table and different parts of it.

Also Read: The Relevant Questions To Ask Your Prospective Cloud Solutions Provider.