Monoclonal antibodies (mAbs) are among the most important biotechnology products for human therapeutics and diagnostics. Over the last few years, dramatic advances in the field have come about through a combination of technological innovations, including mAb screening, directed evolution, and large-scale production. The use of monoclonal antibodies has revolutionized research in immunology, oncology, genetics, and many other fields of medicine that require the analysis and detection of antibodies. The ability to produce mAbs inexpensively has changed the dynamics of basic and clinical research. The mAb product itself is a biological material.

What are Monoclonal Antibodies?

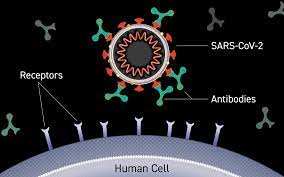

Monoclonal antibodies are a type of protein produced by white blood cells and can target specific cells or molecules. They are used in research and medicine; they are produced in a laboratory and differ from polyclonal antibodies produced naturally by the body. Monoclonal antibodies as protein molecules can bind to target cells.

Monoclonal antibodies are created in the laboratory by cloning B lymphocytes (white blood cells) that have been sensitized to an antigen. The B lymphocytes, also called B cells, are taken from animals like mice, rats, or rabbits and grown in culture with the antigen they have responded to. The animals are given a large dose of the antigen, and then blood samples are taken from them over an extended period. The samples isolate the specific B cells that produce the desired antibody.

Making Of Monoclonal Antibodies

Monoclonal antibodies are made by a complicated process called hybridoma technology, which is based on the natural ability of some white blood cells to “remember” an antigen they encounter. Antigens are foreign substances, such as bacteria, viruses, pollen, and chemicals, that enter the body and stimulate the immune system to produce antibodies. The making of monoclonal antibodies is done in several steps, from the screening of the samples to the eventual production of the antibodies.

The screening process for monoclonal antibodies is critically dependent upon a good target antigen. If a target antigen does not exist, it must be generated. In vitro methods for generating a target antigen for screening purposes include immunization with whole cells or cell lysates, immunization with partially purified antigens, or immunization with cells expressing the desired antigen on their surface.

To optimize the generation of antibodies against intracellular antigens, the antigen can be partially purified by a passage in an affinity column containing peptide ligands that specifically bind to the desired antigenic site. Alternatively, the antigen can be expressed in appropriate host cells and isolated from the culture supernatant. The culture supernatant can then be used to immunize animals for antibody production. We would look into a case study of the Rabbit monoclonal antibodies, which have continued to grow in use over the years for the production of antibodies and research purposes with the coming of the hybridoma technique.

What are Rabbit Monoclonal Antibodies?

Rabbit monoclonal antibodies are antibodies that are manufactured in rabbits or with cell samples from Rabbits. Rabbit monoclonal antibodies are a type of immunoglobulin produced in rabbits. These antibodies are used in research, diagnostic and therapeutic applications. As a research tool, rabbit monoclonal antibodies target specific cells or antigens for observation and study. They can be used to detect diseases such as cancer or identify the presence of infected cells.

Since the Rabbit monoclonal antibodies contain one type of antibody, they can be useful in developing drugs that can be used to treat allergies or other types of disease conditions. In addition, they can be used as diagnostic tools to measure the effectiveness of drugs. Rabbit monoclonal antibodies can be used therapeutically as medications.

Rabbit Monoclonal Antibodies Production

The general stages of rabbit monoclonal antibody production include rabbit immunization, plasma cell isolation, cloning and expression, and screening and selection. The rabbit monoclonal antibodies produced from a single clone are characterized for specific applications (e.g., ELISA, WB, IHC, etc.). The best clone is chosen for scaling up production and performing purification. Because of the expensive and time-consuming process (usually 4-6 months) monoclonal antibody production is typically more expensive than polyclonal antibodies.

Rabbit Monoclonal Antibody Service

The Rabbit Monoclonal antibody service at Boster Bio is second to none in the industry and provides you with accurate results for your Rabbit antibodies from screening to production. Boster Bio offers consultation services to help you decide and make the best choice in choosing where and how to deploy your Rabbit Monoclonal antibodies.

Rabbit Monoclonal Antibody Production Service

Boster Bio’s plasma-cell discovery (PCD) technology uses flow cytometry to screen individual cells treated with proprietary chemistry. This unique compound keeps B cells from secreting antibodies, and retains antibodies on cell membranes. Subsequently, the splenocytes are incubated with fluorochrome-conjugated antigens, and the plasma cells with the highest brightness are screened out for downstream screening and processing.