A linear electric drive is a device that converts the rotational motion of a motor into a linear one. The linear electric drive can be integrated into any equipment for pushing, pulling, lifting, lowering, positioning, or turning a load.

Today, a huge number of actuators of various brands, sizes, capacities, and purposes are presented on the tech market. Such technical units as the electronic actuator are increasingly being applied to automate home space, office space, industry, and more. Just imagine how many interesting projects can be implemented with the help of these small but functional technical devices.

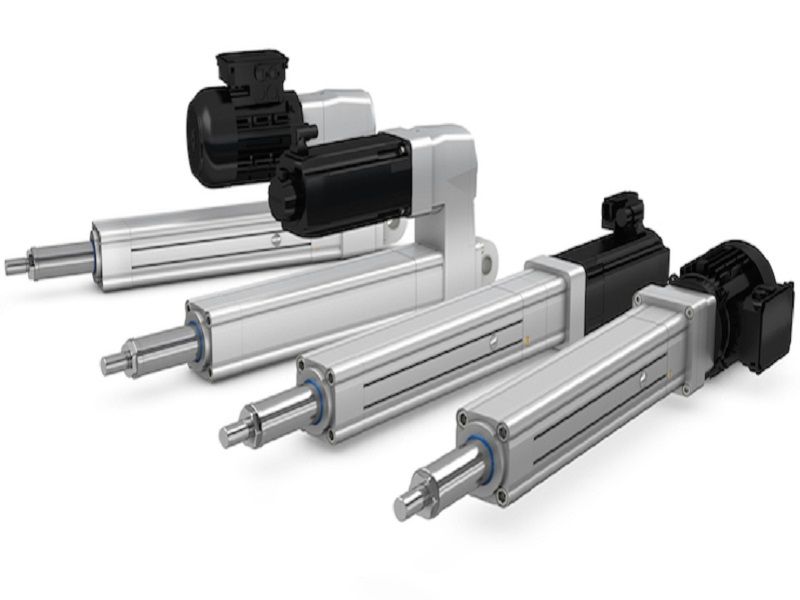

Examples of Electric Actuators

Today, specialized companies develop and manufacture various types of linear electric actuators. They are all interchangeable and customizable according to customer needs and applications.

1. Parallel electric actuators

The motor is located parallel to the worm gear. Parallel actuators are typically driven by spur gears with a wide range of gear ratios. These drives allow for a wider range of loads and speeds but produce a higher noise level than drives equipped with worm wheel gears.

2. Electric actuators located at right angles or L-shaped electric drives

The motor is located perpendicular to the worm gear. L-shaped electric drives are usually driven by worm wheel gears. These drives have a smaller selection of gear ratios than spur gears, so they are considered less efficient but quieter and have higher self-locking force.

3. Built-in electric motors

The engine is located in line with the worm gear. Therefore, built-in electric actuators are characterized by a greater retractable length. They are usually driven by a planetary gear set and are specially designed to work in confined spaces. However, the noise level of built-in drives is higher.

4. Height-adjustable electric columns

For example, it manufactures lifting columns for industrial, medical, and ergonomic applications. Such columns allow you to move large loads vertically and at the same time retain good stability. They are perfect for workplace automation where height adjustment is concerned.

5. Sliding electric actuators

Sliding electric drives allow linear movement without the use of an outer tube. The front mount is connected to a drive nut that travels over the worm screw.

How to Choose the Right Actuator for a Specific Application?

Proper drive selection is essential to any successful automation project. There are many models of drives with parallel, L-shaped, and built-in arrangements of motors. Such models can be used in many areas. Specific conditions require the creation of a unique design solution. To choose the right actuator, you must consider the application and the associated technical constraints, including speed, load, duty cycle, available space, and operating environment.

1. Determining the load

The applied load is a key factor in drive selection and determines the dimensions of drive components (motor, drive nut, threaded parts, gears, ball bearings, etc.).

It is important to determine in which direction the drive should move (whether it should pull, push, or move vertically or horizontally) and how long it should move.

This will also depend on the diameter of the inner and outer tubes of the actuator. All these factors affect the load capacity of the drive and its durability.

2. Speed detection

Speed is a fundamental criterion when choosing a drive.

Not all mechanisms or materials can withstand high speeds. High speed under heavy load can cause premature wear of the drive and affect its life. Therefore, to protect each device from damage, speed and load limits are set that cannot be exceeded. The speed depends, among other things, on the thread pitch and motor characteristics.

3. Determination of the load factor

The load factor, which characterizes the ratio between the time of operation of the device and its idle time, differs significantly for different applications. The load factor is a determining factor when choosing a drive, as well as the materials and mechanisms for its manufacture. This ensures an optimum service life of the equipment and limits the rate of wear of mechanical parts or possible overheating.

Parallel motor drives, such as spur gear drives, can handle higher duty cycles and more cycles.

4. Definition of free space

Drive selection also takes into account available space in the system. In addition to load, stroke, and speed, it is important to consider whether the drive will operate in a confined space if there are space constraints and requirements that need to be taken into account when integrating into a given application.

5. Definition of the working environment

The operating environment in which the equipment will operate is a determining factor in selecting the right drive. Will the equipment work indoors or outdoors? Will it be exposed to dust, particulate contaminants, or moisture? Should you rely on intensive cleaning with detergents or high-pressure cleaning? The materials used and the degree of protection (IP) provided will vary depending on the requirements of the operating environment. Is quiet operation required? L-shaped electric drives, thanks to plastic worm gears, provide a quieter operation, which is ideal for medical or household equipment.