When precise machining is required, particularly for uncommon shapes, broaching is utilized. Circular and noncircular holes, splines, keyways, and flat surfaces are examples of frequently machined surfaces. Small to medium-sized castings, forgings, screw machine parts, and stampings are examples of typical work pieces. An apparatus known as a broaching machine is used to finish surfaces by pushing or pulling a cutter known as a broach completely over and past the surface. A broach is a tool with a row or rows of cutting teeth that are graded in height from the teeth that cut first to the teeth that cut last.

Table up broaching machines

The vertical pull-up broaching machine’s working direction shifts from bottom to top, eliminating the impact and vibration brought on by the vertical pull-down broaching machine’s broaching force, the downward force of the main slide plate and the tool, etc. This significantly increases machining accuracy. The operating surface is low and there is no need to dig a pit because the working direction is from bottom to top. The machine tool has an automatic chip brushing system that can extend the tool’s useful life.

What a broaching machine accomplishes

The majority of the advantages of the new Table-Up Broaching machine are related to the absence of a pit. Table-up broaching machines are ergonomically suited for the workplace and surroundings of today. As there are no gravity-related challenges to deal with, these machines make it simpler for automation to and from the machine.

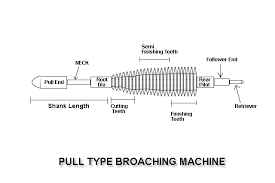

Types of broaching tools

Push broach and pull broach are the two primary categories into which you may divide the majority of broach instruments. Alternative classifications include internal and external broaching machines. Similar techniques are employed by both push and pull broach tools to process materials. The length of a push broach tool must be sufficient to prevent it from breaking or buckling under heavy pressure. When a work piece is pulled across the teeth of a pull broach, which can also be employed vertically as well as horizontally, precise cuts are made.

For a variety of industries and applications, internal broaches can be used to make keyways or other interior holes. A high-speed internal broach is a great tool for producing simple or complex components. To create exterior contouring or defined edges, one uses external broaches, also referred to as internal broaches. This dynamic broaching design can be used to build-up designs for inserts, sections, and indexable tool bits.

The functioning of broaching tools

Depending on the kind of broach tool you’re using, you can experience a variety of precise machining in both soft and hard materials. Boring, shaping, reaming, milling, and boring are all procedures that are competitive with broaching. Broaching may be a better choice for high-production applications. Instead of using separate tools for the rough, semi-final, and finish cutting stages, broaching uses a single tool, or a series of related tools to combine all three degrees of cutting teeth. Broaching is a popular choice for bulk machining of precision components since each of these machining processes may be completed quickly in succession. A dependable broaching machine is required for the perfect broaching tool.

What does push broaching equipment do?

To be able to withstand the compression forces applied as it passes through the workpiece, push broaching tools are shorter. Fewer teeth are present, and because of compressive stresses, they could bend or break. Push broaching creates smaller pieces with shorter cuts. Push broaching tools are frequently used for surface broaching.

What does a pull broaching machine do?

Tools with multiple sets of cutting blades whose cross section grows in size from the top to the bottom of the tool are called pull broaches. While they are often adjusted to reach the necessary tolerance at the tool’s end, the chip breakers at the top of the tool are frequently intended for coarser machining.

Why is pulling more common than pushing with broaches?

Because a broach tool is stronger in tension than in compression, the length of a broach in relation to its diameter may influence whether it must be pulled rather than pushed through the work piece while internal broaching. This in turn aids in selecting the appropriate machine type for the task.

High Speed Pull-Up Hard Broaching Machine

This line of broaching machines has a cutting speed of 0–70 m/min, which is in line with the ideal processing speeds of 50–60 m/min for hard broaching. The broaching machine uses high-rigidity unique ball screws and linear roller guides to assure the equipment’s dependability when driven at high speeds.

Optimize the worktable and machine body designs based on the stiffness analysis. By decreasing the work piece mounting height, an adjustable worktable boosts output. It saves energy and space because there is no hydraulic system.

Servo Spiral broaching machine

The helical broaching process is completed by the broaching machine using a table-up design, synchronous tool rotation, and simultaneous processing of all the helical teeth. Automatic loading and unloading equipment can be added to the broaching machine. The three available modes, left helical, right helical and straight tooth, can be chosen at random. Knife lifting, chip cleaning, and broaching can all be automated. Tool holders for two tools can be made to order.

20 Ton Servo Vertical Table Up Broaching Machine

Low noise, great efficiency, and a 70% reduction in energy use compared to a standard hydraulic broaching machine. Heavy-cut surface broaching machine with high efficiency, machining diversification using a range of jigs and tables, Use high rigidity to sustain high precision over an extended period of time.