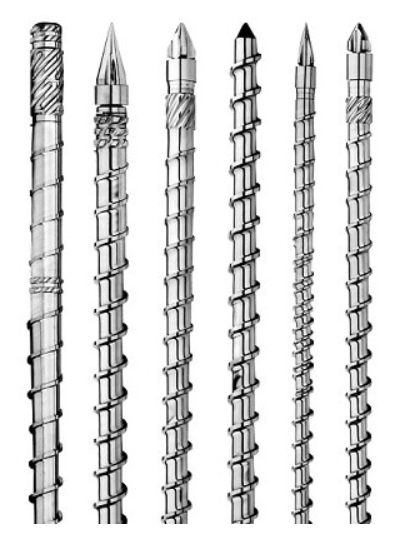

By adopting simpler practices related to plastic processing one can easily extend the life of vital components of any plasticating units. According to the current global market, it has been observed that plastic processors are found to secure a place by incorporating relatively simpler practices concerned with the operation. Starting from injecting mold to blow molding which serves as the key feature for the production of efficiency as well as end products. But the most essential unit for plasticating is the feedscrew and barrel that is designed for the delivery of maximum melting efficiency which flows between the diameter of the barrel wall and the outside diameter of screw flight. The clearance should be maintained at minimal (0.001 in./side, per in. diam.) which serves as the better option for the heat transfer and shearing rate.

When does wearing get started?

With the rotation of the screen inside the barrel, the wearing gets started. Wearing can be visible either on the screw barrel surface or even on both surfaces. If a harder material such as abrasive filler or tramp metal particles is processed then there is a higher chance of faster wear occurrence resulting into increase clearance. With the increased clearance, decreased melting efficiency is observed. The decreased melting efficiency of the original setting tends to balance the increasing screw speed by adjusting the temperature of the barrel and increasing the backpressure along with many other adjustments.

Howsoever, the adjustment helps in avoiding the longer cycle of unmelting material, or material with higher melting temperature or higher scrap rate. Generally, it is changing are observed the incremental but goes unnoticed until drastic impact is levied in terms of quality and productivity. But in the scenario of damage, the amendment cannot take place frequently until and unless there is a spare screw barrel.

Type and causes of wearing:

There are three major types of wearing that can occur and how to identify the major types of wear that are placed on the surface of the screw barrel:

- Adhesive wearing: This wearing takes place when the metal surface such as the screw flight and interior surface of the barrel comes in contact. It is discovered that extremely higher stress is created when the surface of the screw barrel gets in touch with one another either by contacting or welding together. It has been predicted that adhesive wearing can be visible as a burr or rolling over of the trailing system flight landing or when the hard-facing element is scored or missing from the top of the flight. To score better, the barrel needs to be checked for the point where the damage on the screw, located on the barrel is sensed.

- Abrasive wearing: This is the most common type of wearing that is relevant to plastics machinery, especially for the screw barrel. Minimal wearing is observed in the area processed with unfilled or lower viscosity polymer. Whenever pellet gets transported downstream of the screw and induces compression against the barrel wall that results in shearing action causing wearing of the screw barrel. This type of wearing takes place with the processing of resins along with fillers, additives or containments, or even the higher viscosity polymer. The hard material is used for the removal of material from the softer surface. Due to this the flight landing is made of hard-faced with the use of the alloy that is abrasion resistive. Moreover, glass and mineral-filled resins can result in the wearing of screw root that is observed during the rearing of channels before additive wetting as well as melted plastic mixing. With the transportation of pellets down the screw, the barrel wall experiences compression due to the shearing action that levers some degree of abrasion wearing on screw flight and wall of the barrel.

- Corrosive wearing: Corrosion is the most frequent gradual destruction that is caused in material via the action of chemical attacks. Generally, atoms of the same material get oxidized resulting in damage to the entire material surface and it turns vulnerable due to the mechanism of wearing that takes place on the metal surface. Mostly, corrosion is the reaction that takes place in the processing of PVC or polymers belonging to the family of fluoropolymers which aggressively attack the material having higher iron composition.

Closing lines:

This article is published under the supervision of an expert of the reputed Mahira Polyglobal LLP which is recognized as the leading Screw barrel manufacturer in the contemporary market. In this section, we get to know how the wearing of material gets started as well as the three different types of wearing techniques that can take place in the plasticating unit of a screw barrel. Moreover, the detail of every wearing is highlighted which will help in taking precautions before the material requires immediate replacement or other precautionary actions. But in the coming section of the blog focus will be on the mechanism of wearing the plasticating unit.